The Motorcycle Parts New Zealand Specialists Diaries

Table of ContentsSome Known Incorrect Statements About Motorcycle Parts New Zealand Specialists How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The 3-Minute Rule for Motorcycle Parts New Zealand SpecialistsGetting My Motorcycle Parts New Zealand Specialists To WorkThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingRumored Buzz on Motorcycle Parts New Zealand SpecialistsThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe Facts About Motorcycle Parts New Zealand Specialists Uncovered

Get to out to one of our specialists today.CNC machining innovation is swiftly becoming the focal point of various production procedures around the world as a straight outcome of its several advantages over other methods. In addition, the markets that make motorbikes have actually gotten on board with this fad. One of the most ingenious companies are now establishing their engine components and wheels using machining strategies originally developed for motorcycle parts.

You may be asking yourself why we make use of. Currently that we have your focus let us explain the reasoning behind this contemporary advancement in the motorbike production industry.

Some Known Factual Statements About Motorcycle Parts New Zealand Specialists

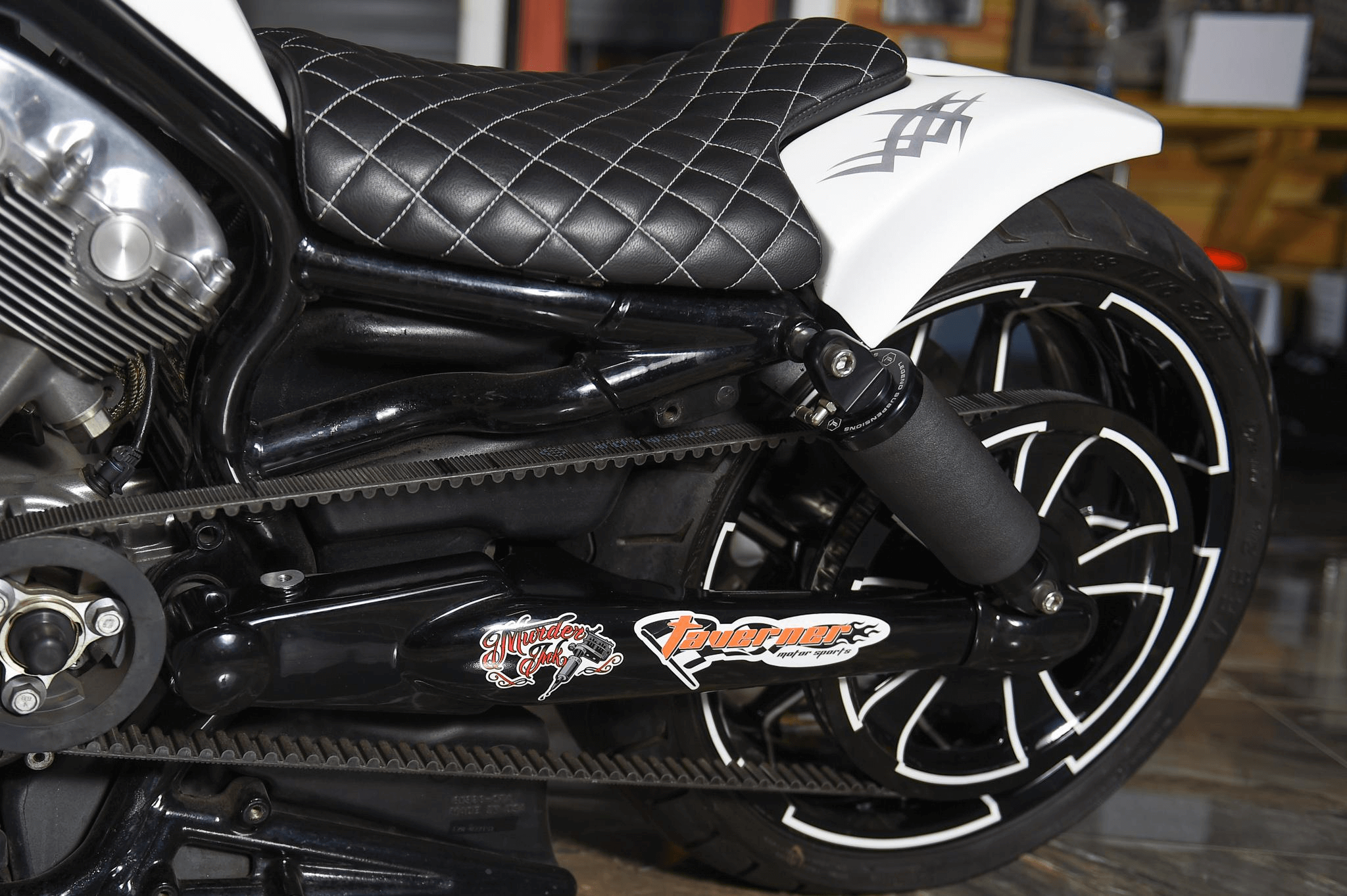

In enhancement, you have total control over the look of the elements, also to the minute information. Sometimes, motorcyclists may make a decision to beautify their experience by setting up aftermarket elements or changing the bike's transformation. Once more, computer mathematical control (CNC) machining is one of the most practical approach. Upgrades might be of any type and style you want.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Shown

CNC machining might be made use of to make almost all of a motorcycle's metal and plastic elements. To proceed, we'll review numerous machined components for bikes.

Milling procedures are used to obtain the desired degree of wheel customization. One more element of the motorcycle that might be individualized is the tires.

4 Simple Techniques For Motorcycle Parts New Zealand Specialists

When it concerns a lorry (or a motorbike), one of the most essential part is the engine. A number of individuals mention it as the "heart" of the automobile. On the other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be elaborate and call for styles with a high degree of accuracy.

Lighting is an additional facility facet of modification. Usage only top quality items, however, because these lights are crucial for the safety of motorcyclists and various other chauffeurs or people when traveling, especially at night. Motorbike headlights have 3 main parts: the light bulb, or source of light, the lens, and the real estate. Particularly, we customize the lens and the real estate.

Milling processes with a remarkable surface would result in the lenses having a reflective high quality that is similar to that of a mirror. The cover, on the other hand, is not made up of breakable products; instead, it is constructed out of tough polymers that can be machined into more elaborate patterns.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking About

Motorcycle makers usually cast these elements, however just for the production of bespoke components. Machining on 5 axes in today's globe is the ways by which any kind of layout form may be understood.

Choose Runsom for your personalized motorcycle parts! We have the capability to produce visit this web-site challenging and stylish parts making your motorbike unparalleled.

Below are a couple of instances of metals typically utilized in bike component machining. Aluminum is the key material made use of by companies specializing in generating custom motorbike elements to develop most of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more steel that is very light in weight and has fantastic machining top qualities due to its high mechanical toughness. This product may be developed into nearly any form and keeps its dimensions well. Even mission-critical parts that need a high level of precision may take advantage of their usage.

The Basic Principles Of Motorcycle Parts New Zealand Specialists

One more steel that sees heavy usage in the manufacturing of CNC-customized parts is magnesium. It is amongst the lightest metals that are currently obtainable and has exceptional machinability attributes and strength commensurate with its reduced weight. Among the downsides of magnesium is that its dirt might easily capture fire.

Their most common usage in creating various motorbike components is bolts, such as screws and bolts. Their low susceptibility to oxidation and corrosion makes them optimal for this use.

Excitement About Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and crushing are the fundamental processes. However, alternate techniques exist, such as boring. Allow's check out a number of these machining methods in depth. The CNC turning strategy is thought about a subtractive manufacturing method. On top of that, it calls for maintaining get more bars of material, usually plastic or metal, in placement and after that twisting a reducing device to remove sections of the material as the product is turned.

These techniques are similarly vital and generate components with high accuracy and consistent high quality. They are respectively: grinding, laser cutting, and exploration. The term "surface area finish" refers to post-processes after the first machining stage. Motorcycle Parts New Zealand Specialists. The procedures assist enhance the general quality of the machined motorbike components. Below are the brief introduction, benefits and drawbacks of five surface area treatment techniques.

Some Known Facts About Motorcycle Parts New Zealand Specialists.